High Precision 4 Axis Woodworking CNC Router 4060 Double Spindle with NC Studio Syntec Richauto Control System for Wood Carving

$3,000.00 原价为:$3,000.00。$2,800.00当前价格为:$2,800.00。

1220 5axis hot wire foam cutting machine

$4,500.00 原价为:$4,500.00。$4,000.00当前价格为:$4,000.00。

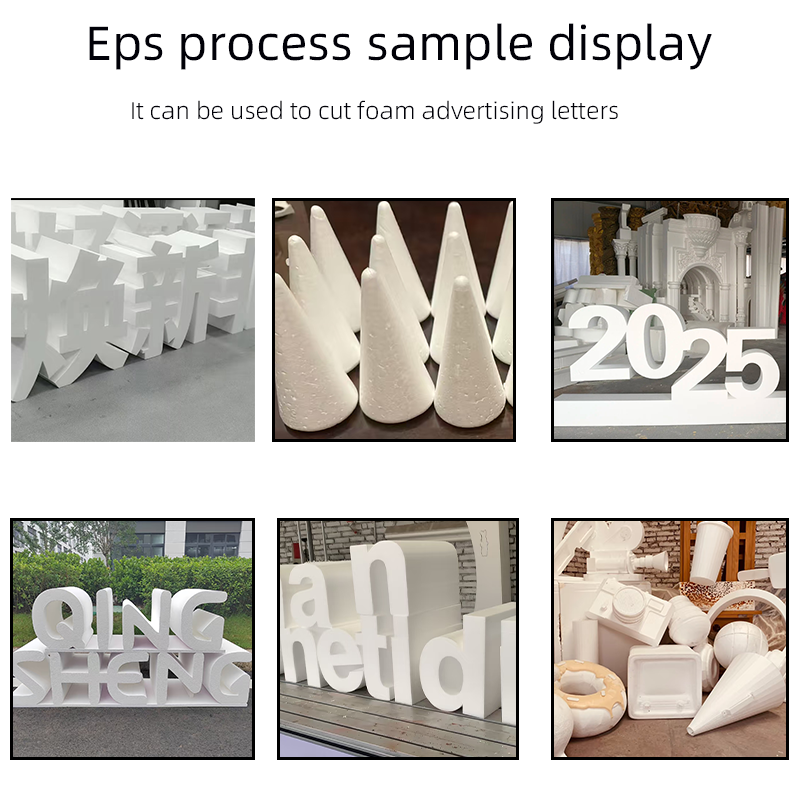

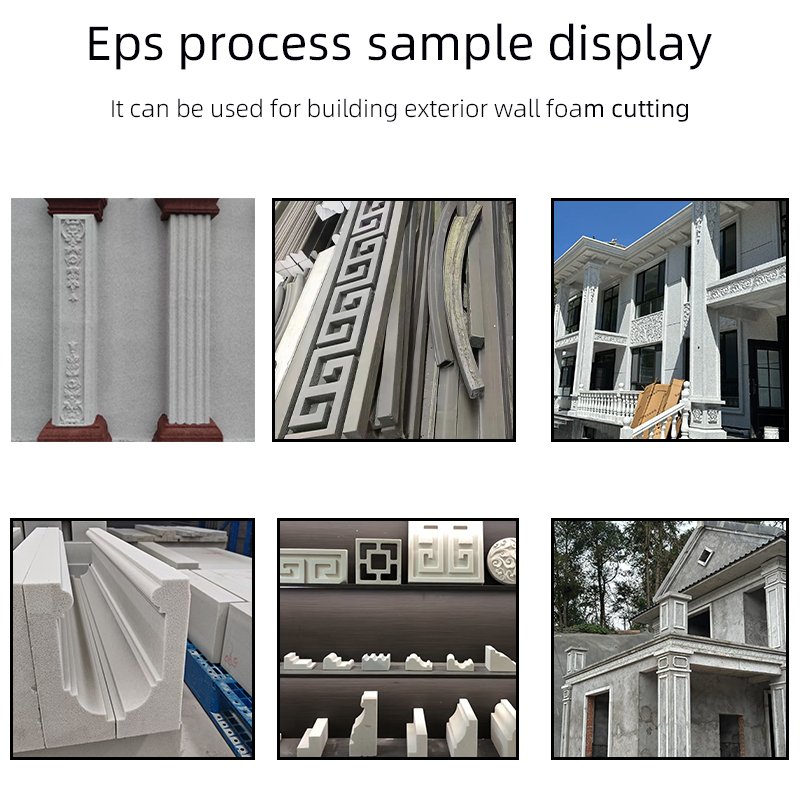

1220 4axis hot wire foam cutting machine for eps &ad words

$3,500.00 原价为:$3,500.00。$3,000.00当前价格为:$3,000.00。

库存 10 件

SKU:

13

分类: 1220 4axis foam cutting machine, Foam cutting machine

描述

Basic Package Include:

Foam cutter

Electronic controller

Foam software (Free updated)

1 years warranty

A roll of hot wire (100 grams)

Operational and assembly manuals

Parameter

| Product Model | 1220 Intelligent CNC Foam Cutting Machine (4-axis) |

| Spindle Regulators | 500w (air-cooled) |

| Overall dimensions | 1520*2500*2060mm(for reference only not limited) |

| operating voltage | 220v |

| work platform | First-class compressed plate for high-density engraving |

| XY travel | (X)1200*(Y)2000*(W)1300mm |

| Repeat Positioning Accuracy | ±0.5mm |

| Gantry | 4*6 square steel gantry |

| Material fixing | Glue gun can be applied or weight can be pressed. |

| foundation | 4*6 high steel structure welding, greatly increase the life of the fuselage (the whole fuselage high heat treatment spray plastic is not easy to deform) |

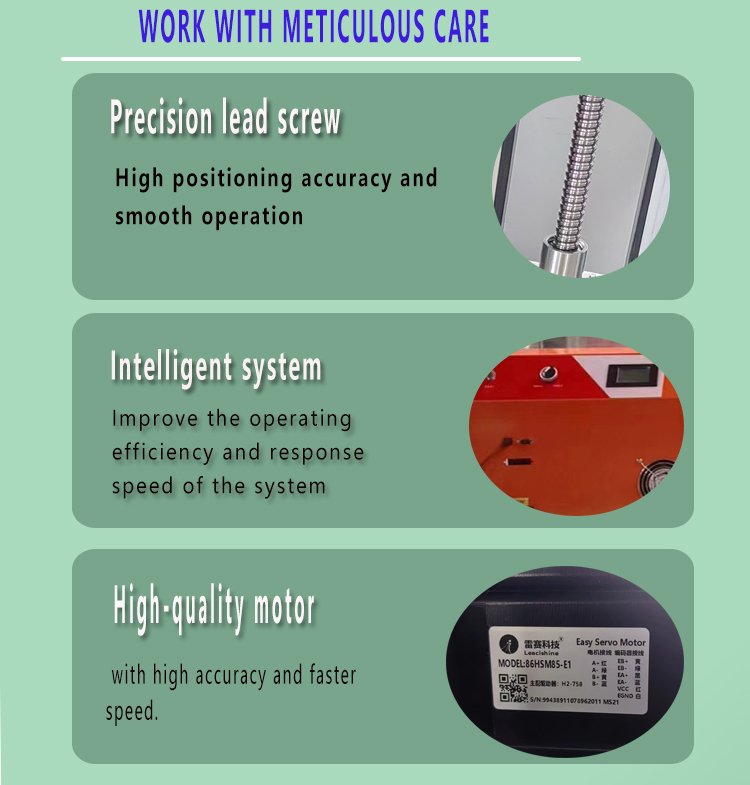

| electrical machinery | X-Y-axis 860 Step Driver X-Y-axis 450B Step Motor Precision engraving four-dimensional |

| operating mode

| Mating X-axis YD860 Y-axis YD860 Digital Stepper Motor Driver |

| XY structure | X-axis 2005 gas-precision anserial + SBR6 round rail, Y1605 high-precision screw + SBR16 round rail (round rail track has the advantages of small friction surface, no noise, wear-resistant and long operating life) |

| X/Y axis guideway | High precision linear SBR16 guideway |

| Heating wire puller | Visit thousands of customers carefully modified easy to install easy to dismantle not easy to break the wire short-circuit power failure easy to cut taper |

| X-axis spindle tension line | Industrial customized spindle motor line 4 * 2 highly flexible shielded wire (anti-interference and anti-static) can be folded millions of times longer life, tension line using high-strength tension is not easy to deform and become long broken line |

| motor cable | Industrial Customized 4*1 High Flexible Shielded Wire (Anti-interference Anti-static) |

| System environment | System environment Windows 7 or 10 64-bit (4G or more RAM, bit) |

| Supported formats | Dwg dxf dc1 jpg bmp jif tif pcx png tga hpg |

| Cutting commands | A key to start automatic heating running automatically back to the far point off heating (fools try to operate with or without experience with a picture can be operated) |

| operating system | Beijing Jingdiao 4D Foam Cutting Machine System |

| switch box | Professional assembly of distribution box team: assembly exquisite one-piece test anti-interference distribution cabinet with a key to switch the two-axis four-axis manual adjustment of the temperature is more convenient |

| regulator | Factory customized exclusive regulator regulator stable and easy to control automatic air-cooled cooling more energy-saving |

| Random Accessory | Imported heating wire fifteen meters 220V power line a customized strengthen the USB link line a 4G USB flash drive storage (programming run) software each set of electronic version of the software package。 |

FAQ

1、What is a foam cutter?

A foam cutter is a tool designed to cut various types of foam materials such as expanded polystyrene (EPS), polyurethane foam, and polyethylene foam. It uses different cutting mechanisms like hot wire, blade, or laser

to shape the foam according to the desired design. For example, in the packaging industry, it’s used to create custom – sized foam inserts to protect fragile items.

2、What are the main types of foam cutters?

to shape the foam according to the desired design. For example, in the packaging industry, it’s used to create custom – sized foam inserts to protect fragile items.

2、What are the main types of foam cutters?

There are mainly three types. Hot wire foam cutters use a heated wire to melt through the foam. The wire is usually made of nichrome alloy, which can reach high temperatures quickly. Blade foam cutters work like a saw, with a sharp blade that slices through the foam. Laser foam cutters use a high – energy laser beam to vaporize or cut the foam. Laser cutters are more precise but also more expensive than the other two types.

3、What materials can a foam cutter handle?

3、What materials can a foam cutter handle?

Foam cutters can handle a wide range of foam materials. They are commonly used to cut expanded polystyrene (EPS), which is often used in packaging and insulation. Polyurethane foam, which is

found in furniture cushions and mattresses, can also be cut. Additionally, polyethylene foam, used for shock absorption and padding, is suitable for cutting with a foam cutter.

II. Regarding operation and use

1、How do I operate a hot wire foam cutter?

found in furniture cushions and mattresses, can also be cut. Additionally, polyethylene foam, used for shock absorption and padding, is suitable for cutting with a foam cutter.

II. Regarding operation and use

1、How do I operate a hot wire foam cutter?

First, make sure the power supply is connected properly and the wire is heated to the appropriate temperature. Then, slowly move the foam along the wire at a steady speed. The heat of the wire will melt through the foam, creating a clean cut. It’s important to keep a consistent speed to ensure an even cut. For example, if you’re cutting a block of EPS foam to make a model, you should move the foam in a straight line and at a constant pace to get a smooth edge.

2、What safety precautions should I take when using a foam cutter?

2、What safety precautions should I take when using a foam cutter?

When using a hot wire foam cutter, always wear heat – resistant gloves to avoid burns from the hot wire. For blade and laser cutters, safety glasses are essential to protect your eyes from flying debris or laser radiation. Make sure the machine is properly grounded to prevent electrical shocks. Also, keep your fingers and other body parts away from the cutting area to avoid accidental cuts.

3、Can I adjust the cutting speed of a foam cutter?

3、Can I adjust the cutting speed of a foam cutter?

It depends on the type of foam cutter. Many modern hot wire and blade foam cutters have adjustable speed settings. You can usually change the speed through a control panel on the machine. For laser foam cutters, the cutting speed can also be adjusted in the software that controls the laser. The appropriate cutting speed may vary depending on the density and thickness of the foam you are cutting.

III. About maintenance and upkeep

4、How do I clean a foam cutter?

III. About maintenance and upkeep

4、How do I clean a foam cutter?

For a hot wire foam cutter, after use, let the wire cool down and then wipe off any foam residue on the wire and the machine body with a dry cloth. For blade cutters, remove the blade carefully and clean it with a brush to remove any foam particles stuck to it. Laser cutters usually have a built – in cleaning system, but you may also need to wipe the lens and the cutting chamber with a specialized cleaning solution to keep them clean and free of debris.

5、How often should I maintain my foam cutter?

5、How often should I maintain my foam cutter?

It’s recommended to do a basic maintenance check after each use. This includes cleaning the cutting parts and checking for any loose connections. For more in – depth maintenance, such as replacing the hot wire or sharpening the blade (in the case of blade cutters), it may be needed every few months or depending on the frequency of use. If you use the foam cutter daily, you might need to replace the hot wire more often than someone who uses it only occasionally.

6、What can I do if my foam cutter is not cutting properly?

6、What can I do if my foam cutter is not cutting properly?

If it’s a hot wire cutter and the wire is not cutting through the foam, check the temperature setting first. The wire may not be hot enough. Also, check for any breaks or kinks in the wire. For blade cutters, a dull blade may be the problem. You can try sharpening the blade or replacing it. In the case of a laser cutter, check the laser power and the alignment of the beam. There may also be software issues that need to be addressed,such as incorrect cutting parameters.

其他信息

| 重量 | 350 公斤 |

|---|---|

| 尺寸 | 170 × 170 × 150 毫米 |

用户评价 (0)

成为第一个“1220 4axis hot wire foam cutting machine for eps &ad words” 的评价者 取消回复

评价

目前还没有评价